These pans are built to fit each fireplace one at a time. Yours will be made just for you.

The

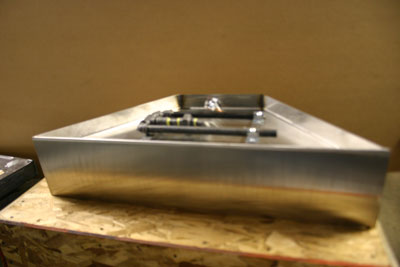

ribbon burner below is made from 1/8" brushed stainless steel. The center was water jet cut and then we bent the two center fins down to install the ribbon burner with

electronic ignition. The base plate measured 94" x 26" and was installed in San Diego, California. The architect is Kelly Crain of San Diego.

Hopefully we will be sent the finished pictures of the fireplace.

We can build these in any size, shape, material and in natural gas or propane. This was tested in the shop with a minimal of 1/4 lb of natural gas. This burner is capable of at least an 18"

ribbon burn. If you look in the center you will see the ignition head for the

electronic ignition.

The fireplace below is on the water in Florida. We built a Ribbon Burner for this Propane Burner and equipped it with an Electronic Ignition. All parts that were used were #316 marine grade stainless steel. The media that was used was a very fine crushed lava.

Mark Cotter was the contractor in Florida who is responsible for this wonderful addition!

The fire pit below is from Chad McGraw in Washington State. He took a simple patio and transformed it into a fire pit and seating area. The electronic ignition was installed under the bench to the left and accessible from the rear of the seating area.

The fire pit below is in Glendale, Arizona at the Renaissance Hotel. We installed an electronic ignition with a 30" stainless steel ring. The glass use was a Clear Base Glass with Starfire Base Glass on top and topped with 42 lbs of Apricot Topper. These pictures were taken with the edges still exposed which were covered by a layer of Starfire Base Glass.

The round pan below is a propane pan with electronic ignition. This is a 36" aluminum pan with a 2" lip all around.

The pan below is a stainless steel pan with a 415,000 BTU electronic ignition installed under the pan. It's what the customer wanted. It's like hooking your car up the the shuttle for more power. This pan was installed in Nipomo/ Pismo Beach California, Shea Homes and we get up there we will take finished pictures as we installed 6 other fireplace which we will take pictures of as well. The front stainless skirt hide the control box which is 4" tall.

|

|

|

|

|

|

The fire pit below was another failed attempt from a company called Fire By Design in Nevada. They helped these customers design a propane fire pit with an electronic ignition (fair at best) and with the lack of knowledge about propane here is the failed attempt. The ring was to placed above the glass according to the manufacture (wrong!). There was no air mixer/ venturi let alone calibrating for proper air mixture to insure a clean burn. The company would not even return any calls to the customer and we repaired the system and made it work properly. This home was on the beach in South Florida.

Several thing went wrong here, wrong filler (lava was too large), Bad cage design over the pilot light/ ignition, they buried the ignition system under the ring and glass, the ring was left on the surface, no air mixer, no customer support, the ring that was supplied was a steel ring for outdoors, wrong! This should of been a stainless steel ring and a strong recommendation for a cover because it was at the beach! We would of also given the option of a #304 stainless steel marine grade ring. We also manufacture our our rings as well.

The next few Propane Pan pictures are of a rake pan. Being 1/2" in the front and 2" in the back. Sitting on 2" legs underneath. We also placed a 2 1/2" metal curtain on the front to conceal the controls and battery compartment. This pan is constructed in steel or can be made from any metal or finish you like. Each of these pans are built for your fireplace specifically. We have very few "off the shelf" items.The remote control allows to adjust from low to medium to high. Testing the Propane Pan at 100,000 btu's. We used a triple 18" burner giving us 6 rows of flames.

If you look closely you can see the battery operated ignition system on the lower right of the pan.

Here is the metal curtain we made. The pan was made to be 3" smaller all around in the fireplace, the front being flush to the front of the fireplace with the metal curtain filling the voids on the sides.

Below you can see the simplicity of the curtain.

The next several pictures show you a flip top box design for a fire pit control panel. It is constructed from stainless steel or could be made from aluminum. The trimming valves are for adjusting the flame are inside along with an electronic key to activate the electronic ignition. These were made for an apartment complex and only the management had control of the electronic ignition. Here are the pictures.

These two separate boxes were made to fit each specific fire pit.

The next fireplace is from Chris Ackopiantz in Palos Verdes California.

Chris lives in a condo complex with only wood burning fireplaces. Chris received permission from his complex to add a propane fed fireplace. Burning wood is not only dirty and nasty, it is very unhealthful as well.

Here are his pictures from beginning to end:

The glass he used was a: